Hansol IONES

www.hansoliones.com

Business areas

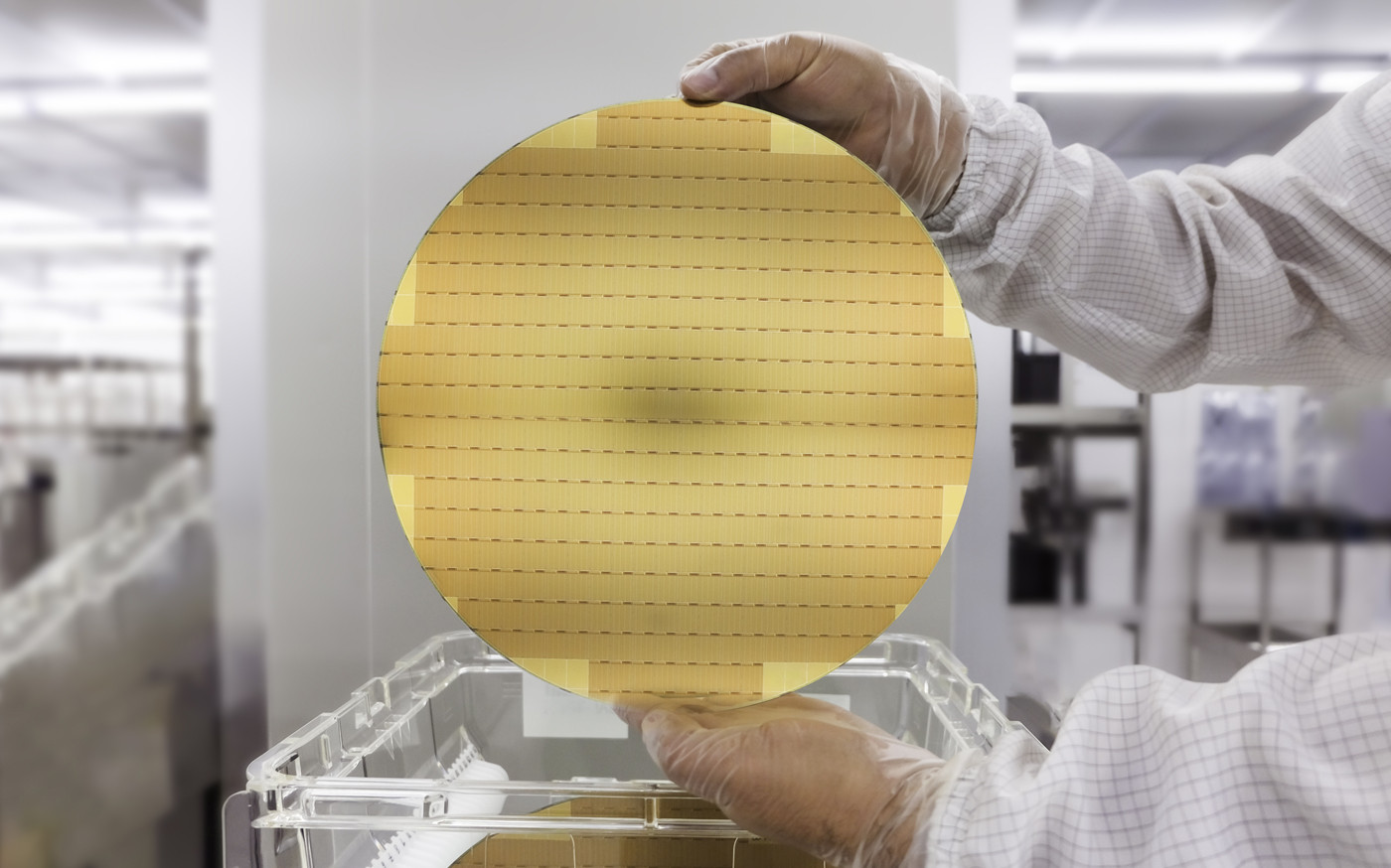

Semiconductor parts manufacturing, cleaning, and coating; display parts manufacturingSupplying ultra-precision parts based on the highest technology and quality to global top-tier semiconductor equipment companies and integrated device manufacturers, Hansol IONES has been proving its distinguished competitiveness. Based on the new material development and nano coating and surface treatment technology, which constitute new growth engines, Hansol IONES will continue growing into a global corporation specialized in integrated parts.